Our Solutions for our Clients

The Best High Precision Injection Molding in Puerto Rico

All products are systematically characterized to establish best operating parameters resulting in a reproducible and repeatable process. Customer to Quality is well defined to gain product confidence and satisfaction.

Our Newest Solutions

Micro Molding Machine for Small and Micro Parts

Unique processing of tiny parts that’s requires a high level of knowledge and Quality Control.

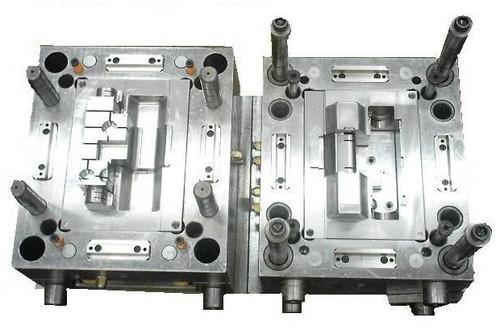

Solutions on Mold Shop Services

In-House Mold Maintenance & Repair

Preventive MaintENAnce

Mold CleanING

Mold Parts Repair

Technical Services

High engagement of subject matter experts to maintain and repair mold conditions effectively.

Mold Shop Services

Tool Manufacturing & Repair

Variety of equipment to create, repair and design high precision tools for In-house molds as well as external enquiries.

technical Services

Tools DesiGN & fabrication

Mold DesiGN & fabrication

Mold Component Analysis

New Mold Lifecycle Process

Project management enforcement system, applied to any product transfer or improvement.

Process Validation

Mold Maker Liason

Mold Flow Analysis

Mold FAT

Techno Plastics Industries, Inc.

Bringing our services about:

CONTRACT MANUFACTURING

(SUB ASSEMBLY)

Help produce plastics parts, or services needed that help the client to reduce cost and equipment.

INVENTORY MANAGEMENT

KANBAN / CONSIGNMENT

Our Kanban inventory system is to continually maintain the minimum amount of stock. Our Kanban system aligns our inventory to client needs.

PARTS QUOTE METHODOLOGY:

MAPP STANDARDS

Best Proposals are defined, adequately foreseen by Manufacturers Association for Plastic Processors.

Quality Assurance Solutions

The quality of our service is our priority

Improving our Quality Assurance Solutions, by combining automated measuring systems with SPC Software, provide the best service to our clients.

Quality Assurance Assistance

Making sure our product are made 100% to the specifications to our clients.

MANUFACTURING SUPPORT

Inspections

Dimensional – Automated System

Functional

Gage R&R

ENGINEERING

Inspections

Dimensional – Automated System

Functional

Gage R&R

Services as needed

WAREHOUSE SUPPORT

Incoming Inspections

Label Inspections

Incoming Resin Inspection

QA SYSTEM

Calibrations

Record Retention / Documentation

CAPA

Customers Complaints

Internal Audit

SOFTWARE & SYSTEMS

Statistical Tools + SPC Software

Process Capability

Measures – Gage R&R